Servicios de Prototipos de Acero Eléctrico

Optimice el diseño y el rendimiento con los servicios de creación de prototipos

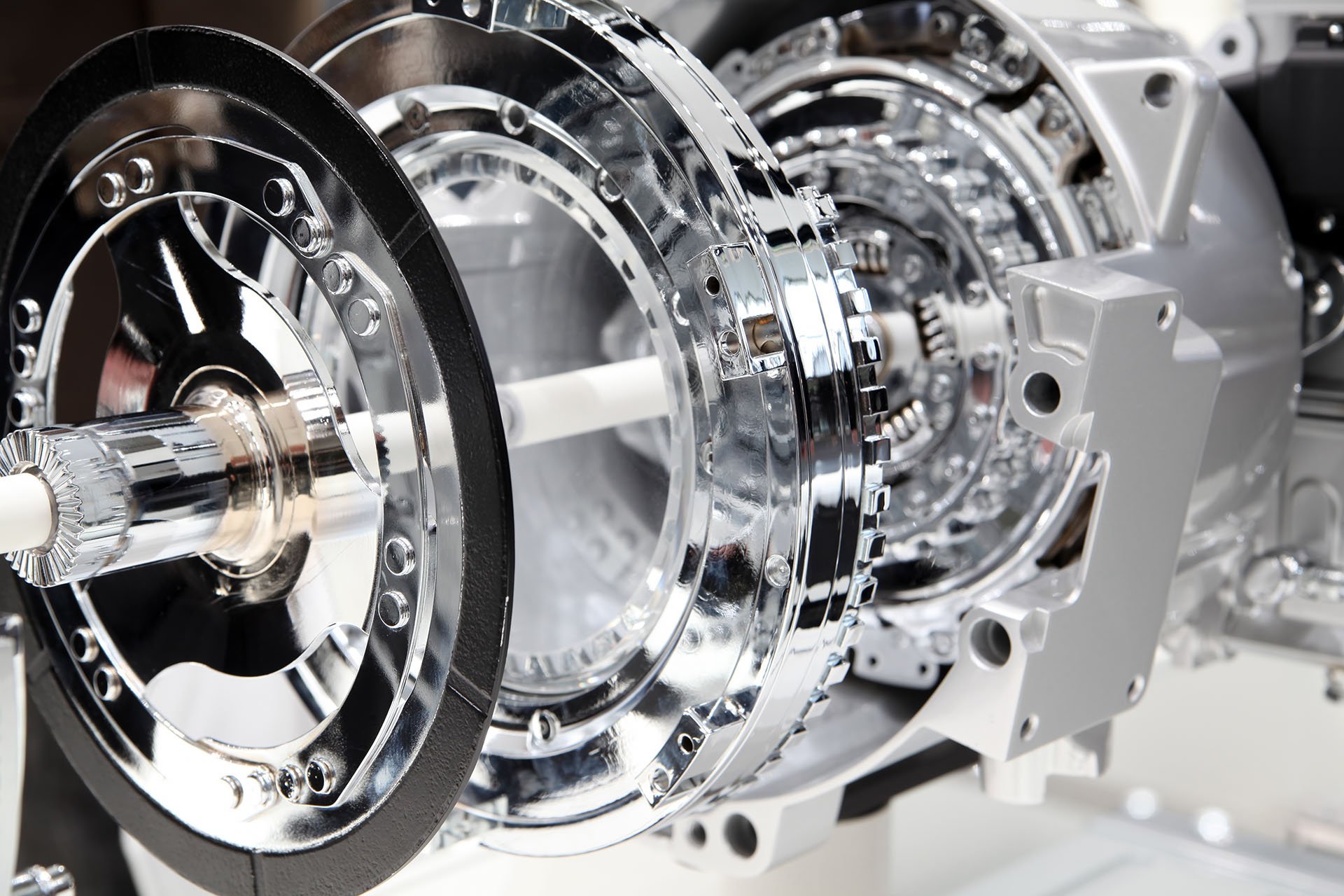

Los servicios de creación de prototipos de acero eléctrico de Tempel pueden dar vida a sus ideas. Nuestro equipo de expertos crea muestras de sus componentes, lo que le permite validar el diseño y el rendimiento antes de la producción en serie. Ofrecemos múltiples opciones, incluídas muestras B, C o Gamma, así como matrices progresivas de elementos de corte de acero con una garantía limitada. Nuestra experiencia en la selección de la calidad y la precisión del acero nos permite crear productos eficientes y de alto rendimiento. Descubra cómo podemos hacer realidad su visión.

Asesoramiento técnico en el diseño

Nos convertiremos en una extensión de su equipo de ingeniería, aportando ideas y conocimientos únicos que le ayudarán a crear mejores productos, con mayor rapidez. Nuestros ingenieros tienen los conocimientos técnicos necesarios para ayudarle a desarrollar nuevos productos o mejorar los existentes.

Concocimiento y Experiencia en Metalurgia

Durante años, Tempel ha trabajado con muestras de acero eléctrico de acerías de todo el mundo para evaluar el rendimiento del acero. Mantenemos una amplia base de datos de evaluaciones de nuevos materiales (NMA por sus siglas en ingles) para ayudar a nuestros clientes a elegir el mejor acero para sus productos.

Pruebas Internas de Alto Rendimiento

Gracias a nuestras capacidades internas de pruebas y validación, podemos trabajar con nuestros clientes desde las primeras fases de desarrollo, identificando nuevas formas de mejorar el rendimiento y la eficiencia antes de que los productos pasen a la producción en serie.

Ahorro de Tiempo y Dinero

No deje que los costosos errores y retrasos hagan que el lanzamiento de su producto fracase. La creación de prototipos con Tempel le permite probar y perfeccionar su diseño desde el principio, lo que acelera el tiempo de comercialización y evita errores costosos.

Reduzca los costos y los plazos de comercialización con los servicios de creación de prototipos en fases preliminares

Desarrollar los Objetivos de Producto y su Rendimiento

Construya Prototipos y Realice Pruebas

Pruebe sus laminaciones, en sus instalaciones o en las nuestras, con los más modernos equipos de pruebas.

Unión

Tempel une los núcleos con numerosos métodos, entre los que se incluyen el grapado, la soldadura, cleating y la unión con adhesivo (bonding). Se trata de tecnologías probadas que proporcionan el mejor rendimiento según los requerimientos del proyecto, teniendo en cuenta las propiedades magnéticas del material. Los núcleos de motor pueden indexarse durante la producción para mejorar factores como el run out, la perpendicularidad y el paralelismo. Además, se puede mejorar el equilibrio de los núcleos del rotor.

Corte por Láser

La mayor precisión y la reducción de la zona afectada por el calor de la máquina crean laminaciones que tienen un rendimiento similar al de las laminaciones estampadas, en comparación con las producidas mediante corte por láser convencional. El servicio de corte por láser de Tempel se centra principalmente en la creación de prototipos de nuevos diseños, pero también puede utilizarse para cortar componentes de acero no eléctricos necesarios para los conjuntos de laminaciones de ventilación o las placas finales utilizadas en nuestros procesos de ensamblaje del núcleo del rotor y el estator.

Optimizar los Prototipos en Función de los Resultados de las Pruebas

La temprana participación en las pruebas y el desarrollo de nuestros productos nos permite mejorar radicalmente sus resultados. Identificamos oportunidades innovadoras para aumentar el rendimiento y la eficacia, y colaboramos con usted para crear nuevos prototipos que, en caso necesario, se someterán a más pruebas.

Finalizar el Diseño para la Producción en Serie.

Tras rigurosas pruebas y prototipos, podemos ultimar los diseños de laminaciones y preparar la producción en serie.

Explora Servicios relacionados

Somos más que un proveedor de laminaciones de acero eléctrico; somos un socio estratégico en la búsqueda de optimizar sus productos. Con nuestras soluciones de vanguardia en procesamiento, estampado e ingeniería, podemos ayudarle a mejorar el rendimiento, la eficacia y la fiabilidad de sus productos.

¿Listo para conectar con el equipo de expertos de Tempel?