Electrical Steel Prototyping Services

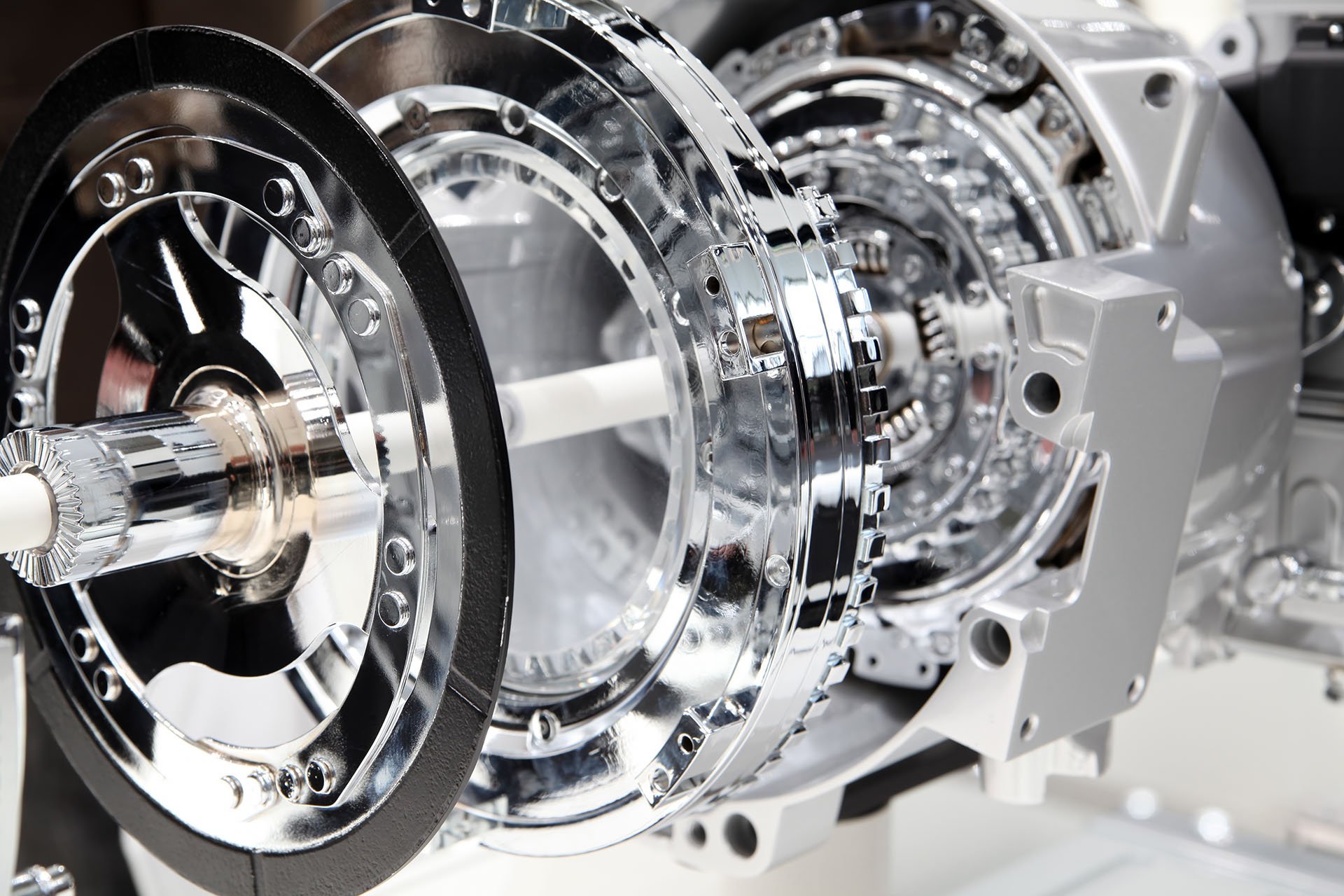

Optimize Design and Performance with Prototyping Services

Tempel's electrical steel prototyping services can bring your ideas to life. Our team of experts create samples of your components, letting you validate the design and performance before mass production. We offer a variety of options, including B, C, or Gamma samples, and steel-cutting element progressive dies with a limited hit guarantee. Prototyping saves time and money by identifying design flaws, reducing manufacturing costs, improving quality control, and facilitating customization. Our expertise in steel grade selection and tolerance empower us to create efficient, high performance products. Discover how we can make your vision a reality.

Technical Design Support

We'll become an extension of your engineering team, providing unique insights and knowledge that will help you create better products, faster. Our engineers have the technical expertise to help you develop new products or improve existing ones.

Metallurgical Knowledge and Expertise

For years, Tempel has sampled electrical steel from mills around the world to benchmark steel performance. We maintain an extensive database of new material appraisals (NMAs) to help our customers choose the best steel for their products.

Extensive In-House Performance Testing Capabilities

With in-house testing and validation capabilities, we can work with our customers from the earliest stages of development, identifying new ways to improve performance and efficiency before products go into mass production.

Time and Cost Savings

Don't let costly errors and delays derail your product launch. Prototyping with Tempel allows you to test and refine your design early on, accelerating your time to market and avoiding expensive mistakes.

Reduce Cost and Time-to-Market with Early-Stage Prototyping Services

Discuss Product and Performance Goals

Our team of experts will use your designs and product requirements to manufacture small batches of laminations for testing. This will allow you to get feedback on your designs and make sure they are meeting your specifications.

Build Prototypes and Conduct Testing

Test your laminations, in your facility or ours, with state-of-the-art in-house testing capabilities.

Unitization

Tempel unitizes cores with numerous methods, including interlocking, welding, cleating, and adhesive bonding. These are proven technologies that provide best performance according to project requirements, taking into consideration the material magnetic properties. Motor cores can also be indexed as they are produced, to improve features such as run out, perpendicularity, parallelism, and with rotor cores, balance.

Laser Cutting

The improved accuracy and minimized heat affected zone of the machine produce laminations closer to the performance seen from punched laminations versus traditional laser cut. Tempel laser cuts laminations primarily focus for prototyping new designs can also be applied to cut non-electrical steel components used for vent laminations assemblies or end plates used in our rotor & stator core assembly processes

Optimize Prototypes Based on Test Results

Early involvement in product testing and development gives us the power to revolutionize your results. We identify breakthrough opportunities to improve performance and efficiency, and we'll work with you to develop new prototypes for additional testing as needed.

Finalize Design for Mass Production

After rigorous testing and prototyping, we can finalize the lamination designs and prepare for mass production.

U.S. patents or foreign patents may apply to this method for the product. Please visit here for more information.

Explore Related Services

We're more than an electrical steel laminations supplier; we're a strategic partner in the quest to optimize your products. With our leading-edge solutions in processing, stamping, and engineering, we can help you improve product performance, efficiency, and reliability.

Ready to connect with Tempel’s team of experts?