Mexico

Contact Info

Tempel de Mexico

Andres Guajardo No. 315

Parque Industrial Apodaca

66600 Apodaca, N.L., Mexico

Phone: +52-818-156-1000

Welcome to Tempel Mexico

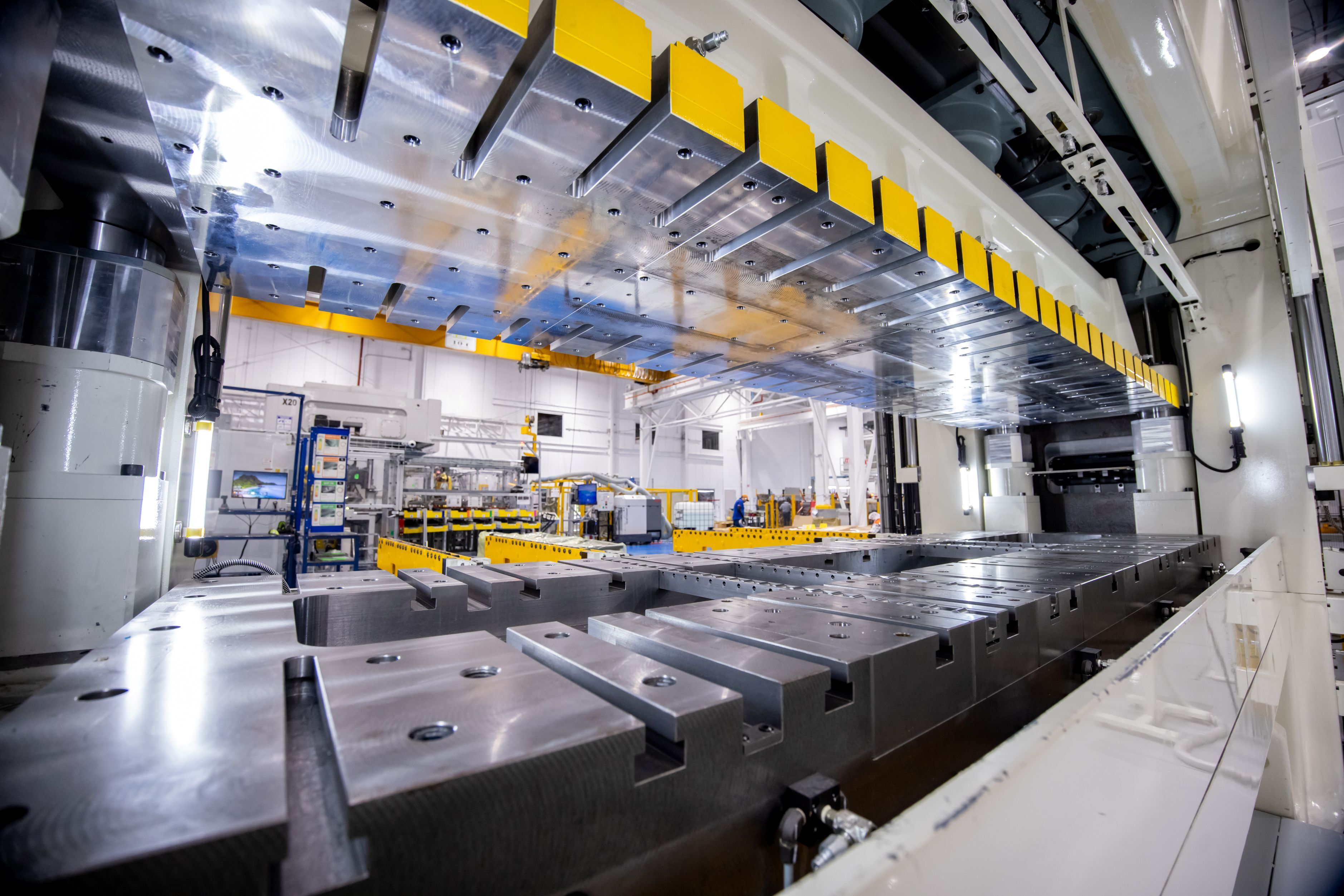

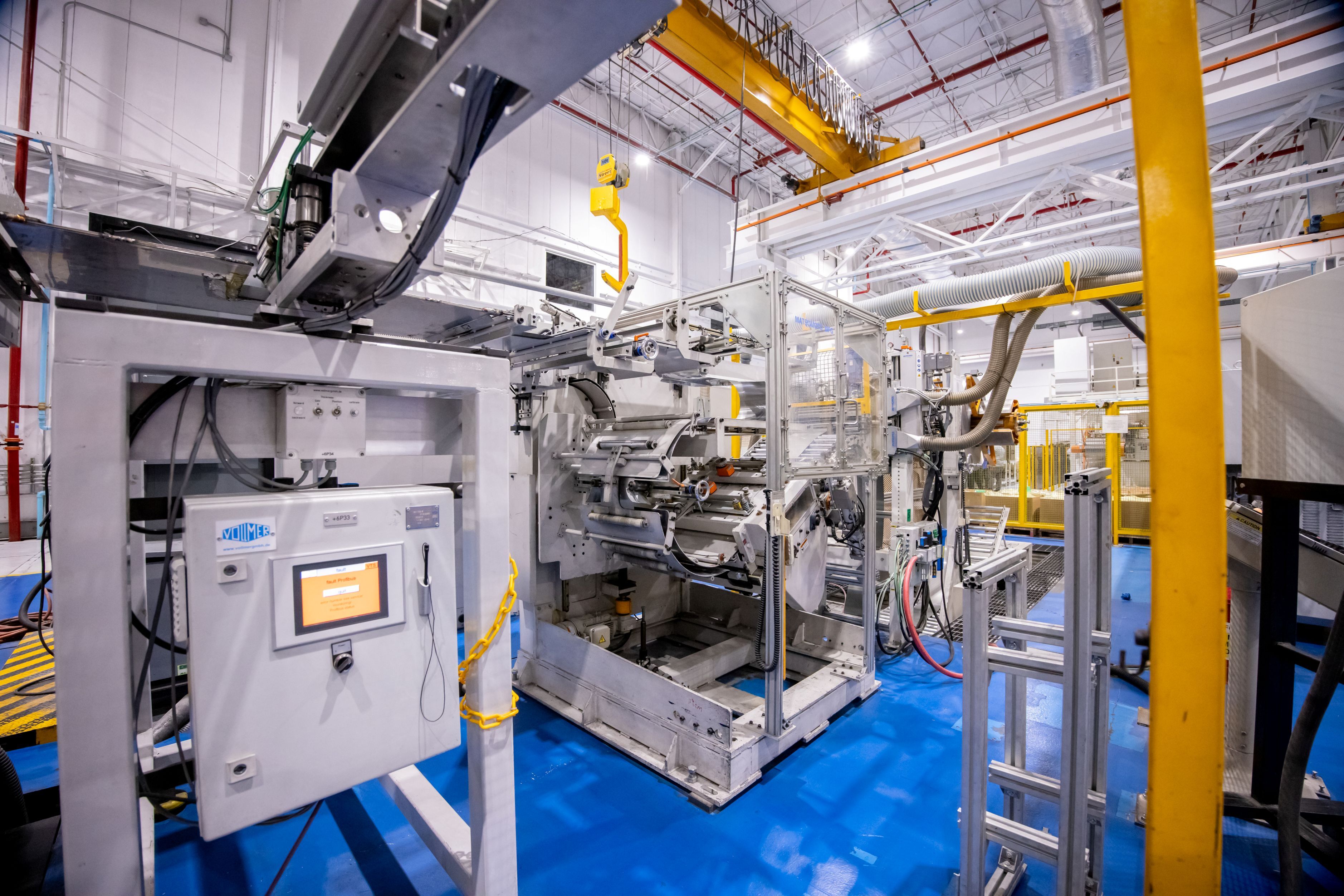

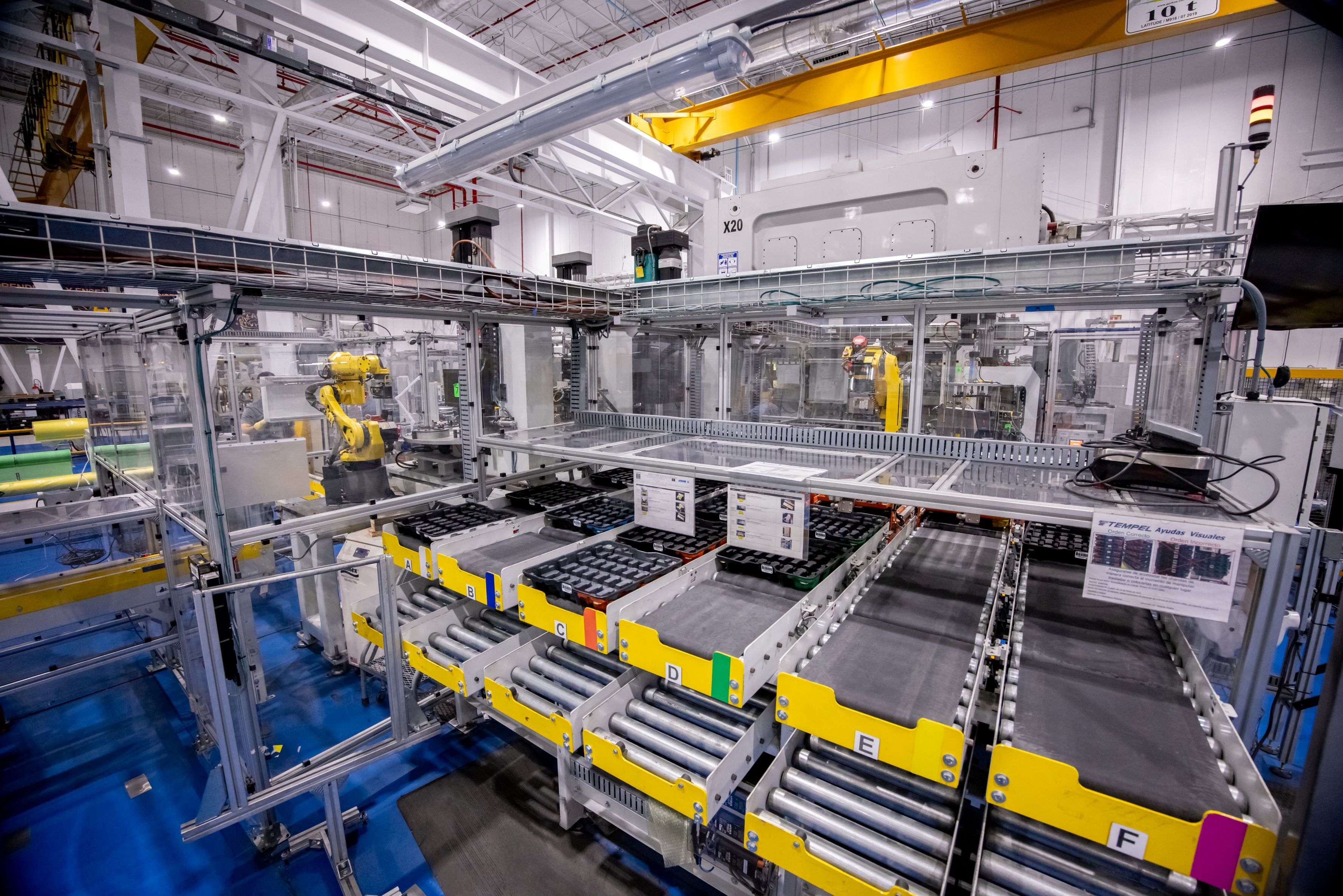

Tempel Mexico is among the largest facilities manufacturing precision magnetic steel laminations. Our 362,991 ft2 facility in Apodaca, Nuevo Leon, Mexico, is strategically located near the international land trading port with the U.S., providing quick and easy access to our customers. Our local team of lamination experts have been in the business for more than 25 years and are committed to providing exceptional products and services. Offering a wide range of lamination services for motors, generators, and transformers, we specialize in steel coil slitting, progressive stamping, blanking, notching, annealing, welding, aluminum die casting, and more.

Explore Our Monterrey Facility

-

Our Specialized Capabilities

- Steel coil slitting

- Progressive stamping with electrical steel ranging from 0.25mm to 1mm thickness

- Blanking

- Notching for large laminations

- Annealing continuous roller heart furnaces with atmosphere control

- Welding, robotic cell GMAW ad alternatives for TIG and laser

- Aluminum die casting for rotors

- distributed gap cores (transformers)

- Stator cleating

- Fully equipped tool room with component design and maintenance capabilities

- Engineering

-

Our Product and Service Offerings

- Laminations for Motors and Generators

- Industrial applications, power generation, oil & gas mining, air moving, wind and hydro pumps, marine, HVAC

- Automotive

- Electric vehicle drives

- Hybrid vehicles

- Alternators

- Ignition

- Power steering

- ABS

- Pumps and cooling

- Seats, window lifters, and wipers

- Laminations for transformers

- power control and quality

- Security

- Medical

- Audio, current

- Steel Services

- Distribution transformers

- Power transformers

- Reactors

- Inductors

- Laminations for Motors and Generators

-

Our Facility Specs

- 381,311 ft2 (35,425 m2) of land

- 362,992 ft2 (33,723 m2) of manufacturing area

- Outside warehouse 125,002 ft2 (11,613 m2)

- active stamping presses (60–600 ton)

- Slitting line

- Continuous roller heart Annealing furnaces

- Automated helical wound core line

- Aluminum Die casters

- Notching

- DG Cores

- Unicore style machines

- Welding cell

- Robotic line for locomotive and large traction motors

- Tool Room

- Wired EDM

- Sink erosion

- Surface grinders

- SIP jog bores

- CNC milling machine

- Cylindrical grinders

- Laser cutter

- Precision grinders

Facility Certifications

.png?width=111&height=109&name=IATF%20certification%20(1).png)

.png?width=172&height=171&name=ISO%209001-2015%20certification%20(1).png)

.png?width=181&height=186&name=ISO%2014001-%202015%20Certification%20(1).png)

.jpg?width=110&height=110&name=C-TPAT%20Certifications%20(1).jpg)

.png?width=111&height=109&name=IATF%20certification%20(1).png)

.png?width=172&height=171&name=ISO%209001-2015%20certification%20(1).png)

.png?width=181&height=186&name=ISO%2014001-%202015%20Certification%20(2).png)

.jpg?width=110&height=110&name=C-TPAT%20Certifications%20(1).jpg)

.png?width=111&height=109&name=IATF%20certification%20(1).png)

.png?width=172&height=171&name=ISO%209001-2015%20certification%20(1).png)

.png?width=181&height=186&name=ISO%2014001-%202015%20Certification%20(1).png)

.jpg?width=110&height=110&name=C-TPAT%20Certifications%20(1).jpg)

.png?width=111&height=109&name=IATF%20certification%20(1).png)

.png?width=172&height=171&name=ISO%209001-2015%20certification%20(1).png)

.png?width=181&height=186&name=ISO%2014001-%202015%20Certification%20(2).png)

.jpg?width=110&height=110&name=C-TPAT%20Certifications%20(1).jpg)

.png?width=111&height=109&name=IATF%20certification%20(1).png)

.png?width=172&height=171&name=ISO%209001-2015%20certification%20(1).png)

.png?width=181&height=186&name=ISO%2014001-%202015%20Certification%20(1).png)

.jpg?width=110&height=110&name=C-TPAT%20Certifications%20(1).jpg)

.png?width=111&height=109&name=IATF%20certification%20(1).png)

.png?width=172&height=171&name=ISO%209001-2015%20certification%20(1).png)

.png?width=181&height=186&name=ISO%2014001-%202015%20Certification%20(2).png)

.jpg?width=110&height=110&name=C-TPAT%20Certifications%20(1).jpg)

Explore Current Careers Across Tempel

Discover a workplace that allows you to start, grow, and advance your career. By offering our people competitive compensation, development programs, and comprehensive benefits and perks, we create a workplace that allows everyone to thrive.

News and Resources

Get in Contact with an Electrical Steel Expert