Progressive Stamping

Precision and Expertise in Progressive Stamping Methods

Progressive stamping shapes sheet metal in stages, each adding a characteristic to the piece. It requires the expertise of disciplined engineers and tool and die makers who can execute the most complex metal stamping operations with high precision. Tempel’s 75 years of experience enables our team to design and build quality progressive tooling to meet our customers’ high-end lamination needs, from the initial strip layout to selection of all required steel and carbide components.

Material Savings

Progressive stamping minimizes scrap material and waste, lightening your project’s environmental impact.

Increased Productivity

Progressive stamping can create multiple parts with a single pass through the dies. Our facilities are equipped with the latest in process flow equipment, including precision presses and state-of-the-art feeding systems, to complete your project with efficiency and precision.

Enhanced Product Quality

With its precise and repeatable process, progressive stamping ensures parts are consistent, accurate, and free of defects.

Reduced Assembly Cost

Progressive stamping is a cost-effective way to quickly and efficiently produce high-volume parts, reducing labor costs and material waste.

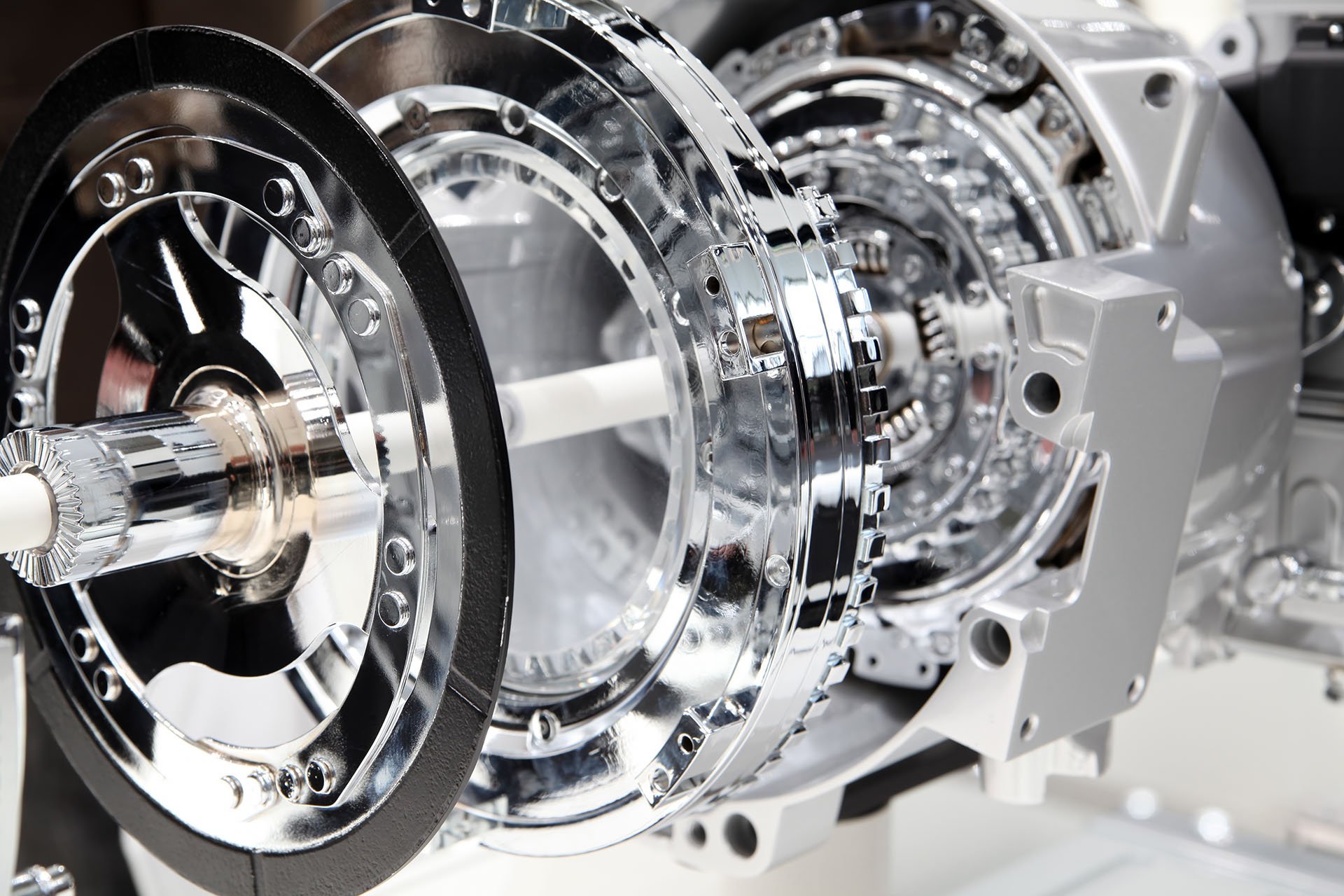

Progressive Stamping Process

Material Preparation

The electrical steel material is material is slit to width and loaded into the progressive stamping system (slit, de-coil, flatten or straightening).

Feeding

The material is fed into the stamping system, and it progresses through the various stations, each producing specific part features.

Stamping

The steel strip moves through the die stations with different part features being stamped at each station. In the final station, the part is punched from the strip and harvested from the die.

Post-Stamping Processes

The laminations undergo finishing processes such as annealing, welding, bonding, and more to ensure they meet required specifications and standards.

U.S. patents or foreign patents may apply to this method for the product. Please visit here for more information.

Explore Related Services

We're more than an electrical steel laminations supplier; we're a strategic partner in the quest to optimize your products. With our leading-edge solutions in processing, stamping, and engineering, we can help you improve product performance, efficiency, and reliability.

Ready to connect with Tempel’s team of experts?