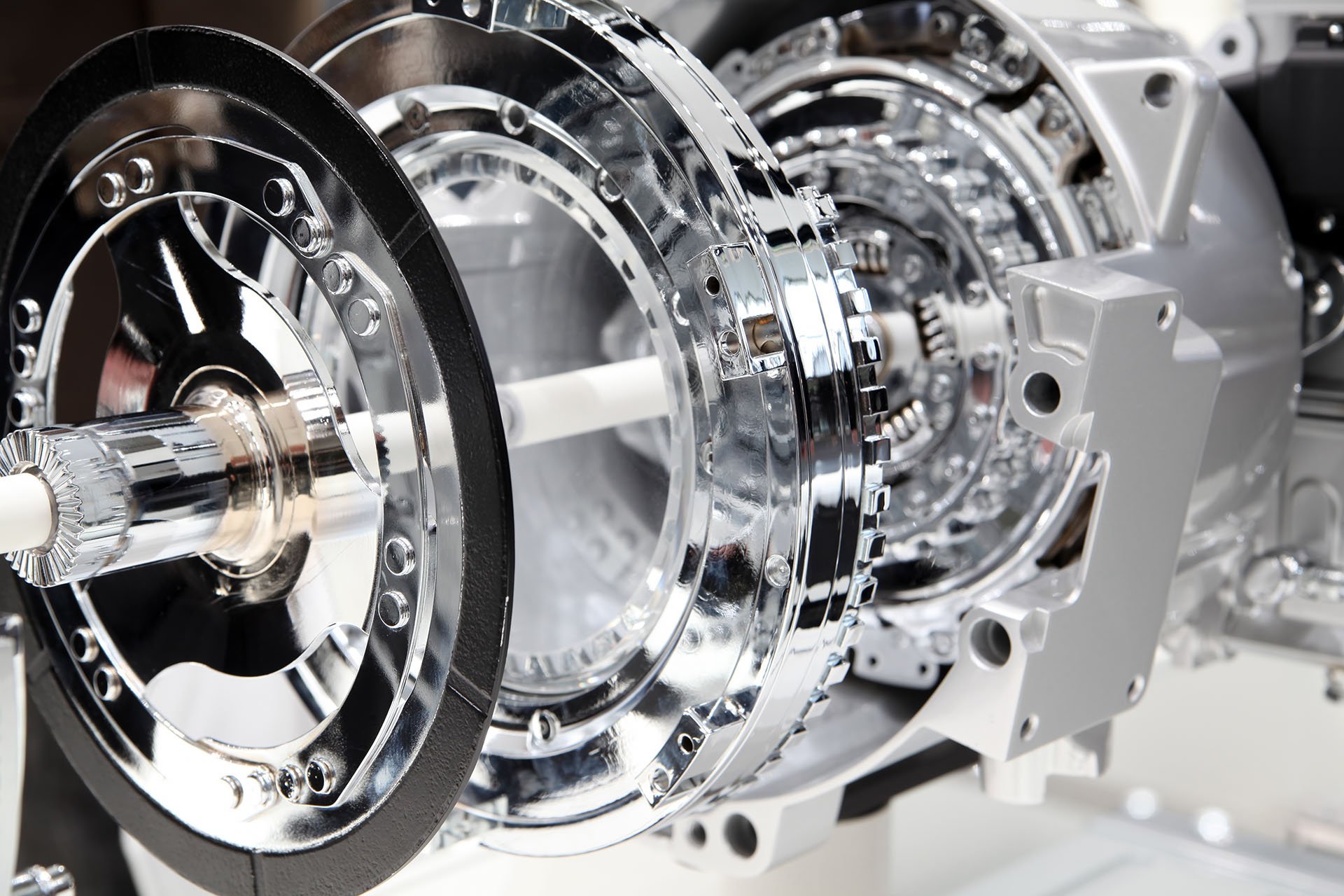

Motors and Transformers Design and Engineering

Laminations Design and Engineering for Performance & Reliability

Whether you're launching a new motor or transformer program or improving your existing processes, Tempel’s design and engineering capabilities can help you get the job done. We’ll collaborate with your engineering team to align your product needs with our technical expertise, and we'll provide you with the insights and recommendations you need to fuel success.

Advanced Engineering Support

Working as an extension of your engineering team, we provide unique insights and knowledge to help you create better products, faster. Our engineers have the technical expertise and experience to help you develop new products, improve existing ones, and optimize your manufacturing processes.

Metallurgical Knowledge and Expertise

For over 75 years, Tempel has sampled electrical steel from mills around the world to benchmark steel performance. We maintain an extensive database of new material appraisals (NMAs) to help our customers choose the best steel for their products.

Highly Skilled Tool Makers

Our network of highly skilled tool makers around the world and in-house tool maintenance teams turn designs into high-performing dies that last.

Innovation and Excellence Engineered into Every Motor and Transformer

Identify Needs and Develop Initial Design Concepts

Our engineering and die experts will collaborate with you to understand product requirements and production goals to begin drawing up initial die concepts.

Test and Validate Design Concepts with Engineer Team

After collaborating on a custom die design, our team will conduct rigorous tests to validate these concepts with the engineering team and fine-tune your designs.

Finalize Design and Begin Die Build

With the design finalized, we send the product drawings to esteemed die building experts to begin constructing the final product.

Conduct Quality Assurance Tests

After receiving the die at our facility, we’ll conduct final quality tests to ensure the die is working as intended and is ready for production.

Begin Lamination Production

Once the die has passed all quality assurance reviews, it enters production stage to start stamping your custom laminations.

U.S. patents or foreign patents may apply to this method for the product. Please visit here for more information.

Explore Related Services

We're more than an electrical steel laminations supplier; we're a strategic partner in the quest to optimize your products. With our leading-edge solutions in processing, stamping, and engineering, we can help you improve product performance, efficiency, and reliability.

Ready to connect with Tempel’s team of experts?