Tempel Applied Bonding

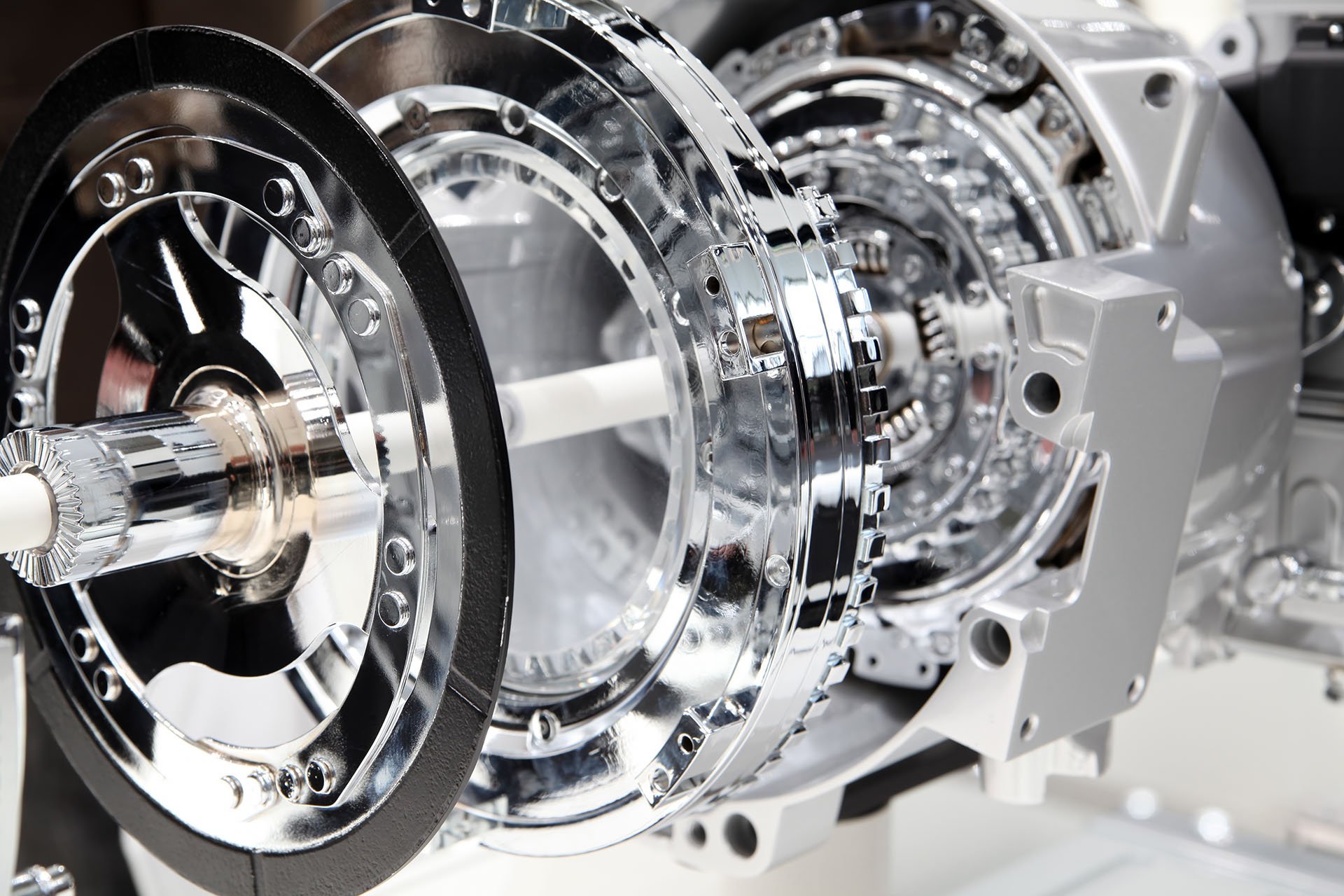

Glue Dot and Full Surface Bonding Capabilities

Traditional methods of unitizing motor cores, such as interlocking and welding, can lead to interlaminar shorts. Tempel's bonding methods eliminate interlaminar shorts and improve the overall performance of your motor and transformer. We offer glue dot, full surface bonding, and provide the ideal bonding method for your cores.

Improve Magnetic Performance

Minimize interlaminar core loss and corrosion while improving magnetic performance with innovative bonding technologies from Tempel.

Enhance Product Quality

Bonding is a preferable alternative to welding or interlocking to reduce the noise, vibration and harshness (NVH) of motors, improve thermal conductivity, and minimize risk of core damage during downstream processing.

Technical Support

Our in-house experts, technology, and capabilities will help you find the perfect bonding method to make your product last.

Lamination Core Bonding Capabilities

Lamination Bonding Prototypes

Unsure of the best bonding technology? Our team will create prototypes of both options so you can see for yourself which one is right for you.

Glue Dot Bonding

Glue dot bonding is applied within the die. The cores are then cured in the oven and fused together.

Full Surface Bonding

With full surface bonding, the coating is applied to the laminations outside of the die and then oven-cured to become fused.

U.S. patents or foreign patents may apply to this method for the product. Please visit here for more information.

Explore Related Services

We're more than a supplier of electrical steel laminations; we're a strategic partner in the quest to optimize your products. With our leading-edge solutions in processing, stamping, and engineering, we can help you improve product performance, efficiency, and reliability.

Ready to connect with Tempel’s team of experts?