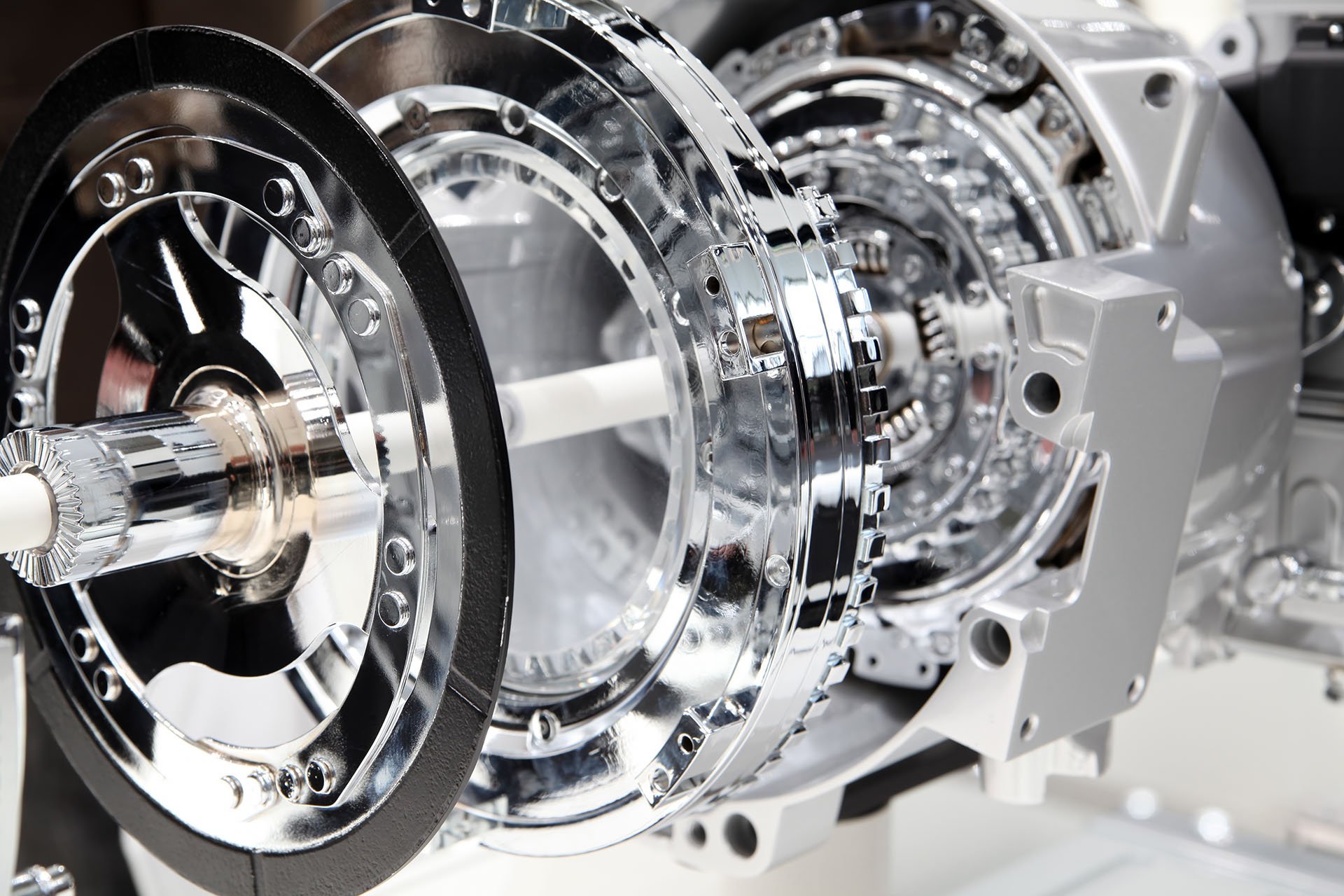

Precision Tooling and

Die Engineering

Complex Tool Designs and Quality Engineering to Achieve Unmatched Electrical Steel

Lamination Precision

Tempel's 75+ years of experience in tooling design and manufacturing means you can trust us to deliver the highest quality complex tooling for your motor and transformer applications. Our team of experts understands the precise requirements for manufacturing and die design. We select the best steel and carbide components and build top quality tooling to meet your specific needs. Whether you need tooling for high-end laminations or complex custom designs, we can help.

Custom Tool Design

Precision tools that meet your exact needs start with a deep understanding of your requirements. Our team of experts will study your prints and specifications to ensure the finished tool is perfectly suited to your application.

Highly Skilled Tool Makers

Our in-house experts carefully evaluate and design specialized tools. With the flexibility to leverage our global network of industry-leading tool makers, we can build the highest quality tools for our customers, no matter what their needs.

Quality Control

Tempel's quality assurance process is one of the most effective and thorough of any lamination supplier in the world, including detailed reviews and audits to ensure continuous adherence to quality improvement assessment requirements and VDA6.3 requirements.

In-House Die Maintenance and Upkeep

We have a fully self-sufficient asset management database with tooling maintenance and repair capabilities to monitor tooling condition, die life, repairs, and preventative maintenance

Precision Tool and Die Engineering Process

Create Custom Die Designs

Our experts carefully evaluate the customer prints to determine what tolerances are achievable and provide recommendations on the method of measurement for complex geometry design.

Produce Strip Layout

We review the customer's prints to understand how the tool will be laid out, looking for ways to maximize the length of the tool, optimize material utilization, and meet tight tolerances. Once we have a layout that meets our requirements, we get to work.

Review Tooling Station

Tooling stations are reviewed to carefully select features such as index rotation, solid mount or floating punches, embossing design, and piloting system.

Select Press

After tooling features are chosen, we select the appropriate press for the job.

Determine Tool Builder

We use supplier-based knowledge to choose the right tool builder for the project.

U.S. patents or foreign patents may apply to this method for the product. Please visit here for more information.

Explore Related Services

We're more than an electrical steel laminations supplier; we're a strategic partner in the quest to optimize your products. With our leading-edge solutions in processing, stamping, and engineering, we can help you improve product performance, efficiency, and reliability.

Ready to connect with Tempel’s team of experts?